watttron

Wir optimieren

die Fertigungswelt von morgen.

Mit der disruptiven Technologieplattform gibt watttron seinen Kunden ein umfassendes Verständnis und die volle Kontrolle über ihre thermischen Prozesse, um die beste Qualität zu liefern und maximale Effizienz zu erreichen.

Fortschritt liegt uns in den Genen

News • News • News • News • Wir freuen uns, Sie bei den kommenden Events zu begrüßen:

FachPack Nürnberg 24. - 26. September 2024 • Pack Expo Chicago - 3. - 6. November 2024 • News • News • News •

Thermoformen

Siegeln

Simulation services

Monitoring

Infrastruktur

Digitale Heizsysteme

Thermoformen

cera2heat: Die nachhaltigste Art der Thermoverformung

Nachhaltigkeit und Effizienz sind keine kurzfristigen Trends – sie sind die Zukunft. Und wir bieten die Lösungen dafür. Für alle Industriebereiche. Für verschiedenste Anwendungen. Und als maßgeschneiderte Entwicklungen für kundenspezifische Anforderungen.

Unser patentiertes Matrix-Heizsystem cera2heat® ermöglicht eine heterogene, genau definierte Kontakterwärmung von Oberflächen.

Digitale Heizsysteme

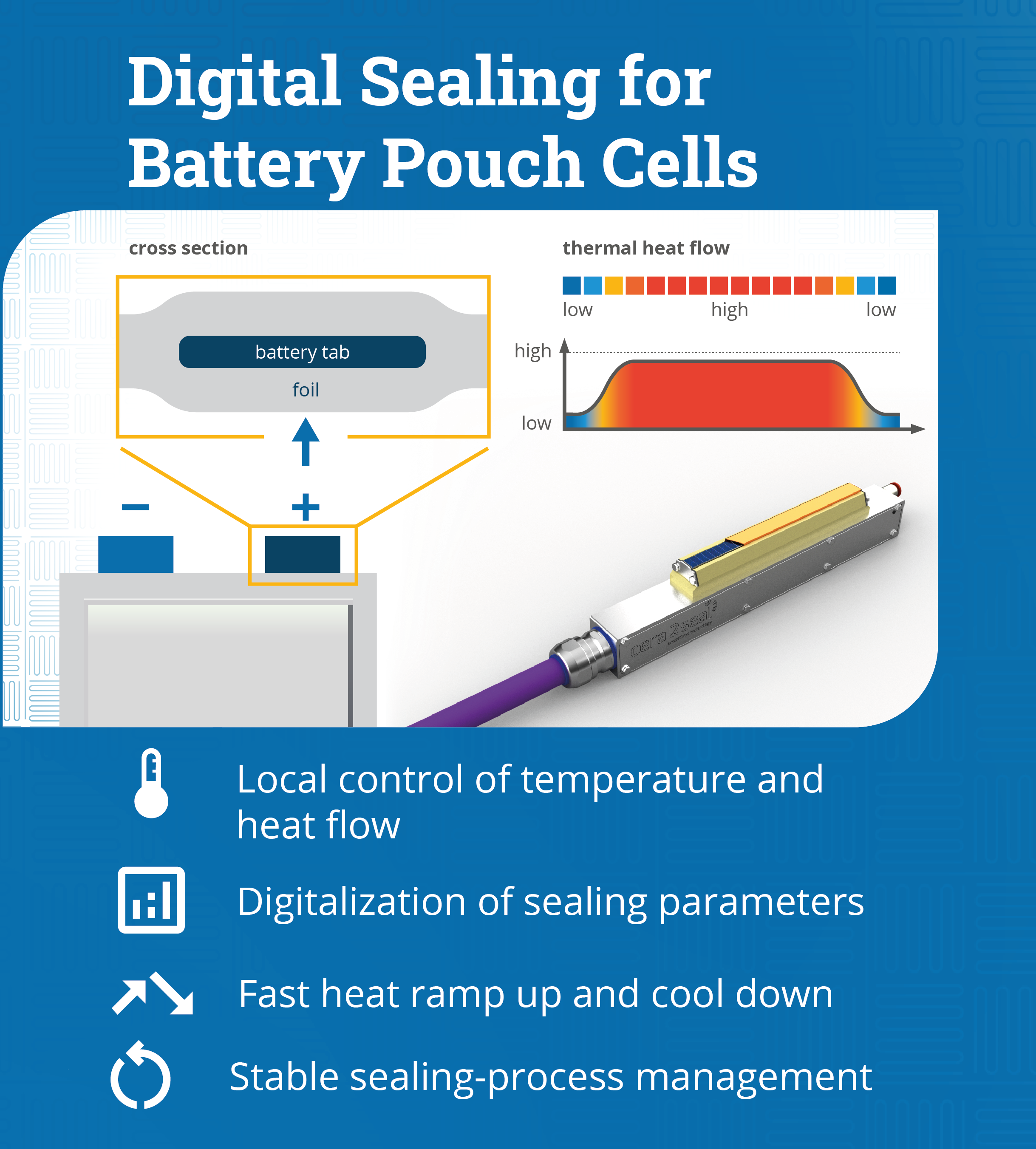

Siegeln

cera2seal: Die effizienteste Siegel- und Schweißtechnologie seit der Erfindung der Verpackung

Unser Heizsystem cera2seal® ist speziell auf Siegel- und Schweißprozesse ausgelegt.

Damit lassen sich weltweit erstmalig komplizierte Verpackungs-Geometrien umsetzen – beispielsweise komplexe unregelmäßige Formen. Aber auch Ringe mit verschiedenen Durchmessern und Breiten sowie Siegelschienen mit angepasster Breite und Länge.

Digitale Lösungen

Simulationsservice

Planbare Effizienz und Nachhaltigkeit

Dank unserer Simulationssoftware sind wir in der Lage, verschiedenste Produktlayouts zu simulieren und den Einfluss äußerer Einwirkungen auf diese Produkte nachzustellen. Hierzu führen wir eine virtuelle Materialmodellierung durch, in die wir alle relevanten physikalischen Parameter einfließen lassen.

Heating Solutions

Monitoring

Visuell unterstützte Ansteuerung und Überwachung

Unsere Technologie ist mit einer programmierten Bildoberfläche verbunden, die im Wesentlichen drei Funktionen unterstützt:

1.Ansteuerung: Visuell unterstützte Programmierung der Heizer.

2. Functional Monitoring: Abbildung des aktuellen Fertigungsprozesses und Fehlerüberwachung.

3. Power Monitoring: Misst die aktuelle Energieaufnahme des Systems und erkennt dabei Anomalien im Fertigungsprozess.

Heating Solutions

Infrastruktur

Maximale Potentiale aus der Cloud

Verwalten Sie Ihre Heizer aus der Cloud und nutzen Sie alle Vorteile:

• Zugriff über eine geschützte Infrastruktur mit Rollen-Rechte-Verwaltung

• Hochladen von CAD Daten zur Erstellung eines Heizprofils mittels Simulation

• Anpassung der Heizprofil-Parameter nach Bedarf

• Automatische Benachrichtigung zu Fehlern oder zu empfohlenen Wartungsmaßnahmen

• Bereitstellen von Kalibrierdaten

Coming soon!

Anwendungsbereiche

Kunststoffverarbeitung

Kunststoffverarbeitung

Schlauchbeutel und weitere (Um)-Verpackungen für sterile Produkte

Verpackung

Verpackung

Mehr Effizienz, weniger Verpackung

Additive Fertigung

Additive Fertigung

Mehr Effizienz, weniger Verpackung

Chemie

Chemie

Neue Materialien wie Monomaterial

Mikroelektronik

Mikroelektronik

Umformung von SMD-bestückten Folien

Mobilität

Mobilität

Neue Möglichkeiten für den Leichtbau

Biotechnologie

Biotechnologie

Temperierung für Labortechnik und analytische Verfahren

Medizin

Medizin

Schlauchbeutel und weitere (Um)-Verpackungen für sterile Produkte

Termine

News

3. – 6. November 2024

Wir freuen uns, Sie an unserem Stand Nr. 2287, Halle Süd, auf der PackExpo in Chicago einzuladen. Nutzen Sie die Gelegenheit, mit uns über die neuesten Entwicklungen im Bereich der digitalen Siegelung zu sprechen.

Wir freuen uns auf Sie!

News

Auszeichnungen

Auszeichnungen