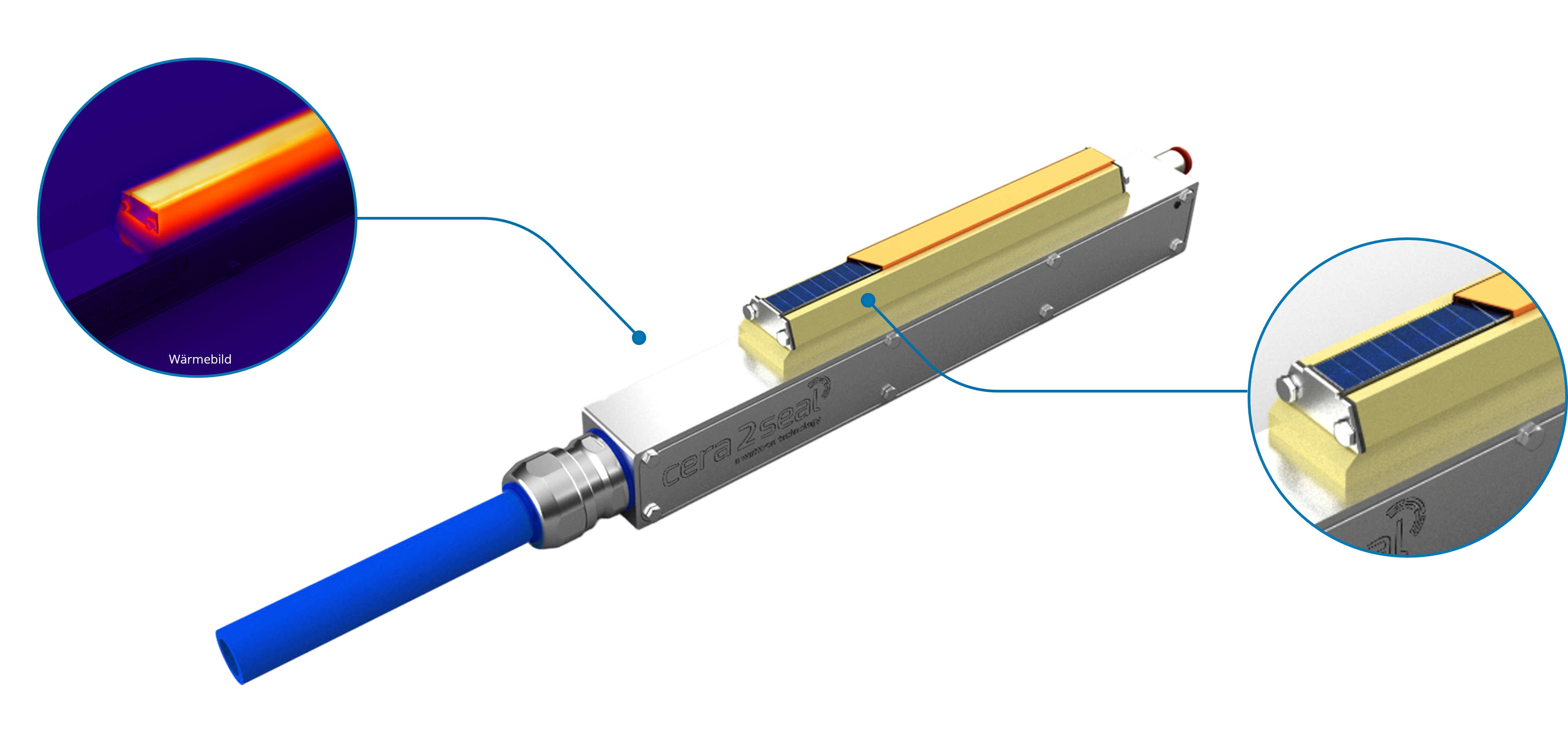

Individually controllable heating pixels spaced 5 mm apart

Precise temperature control for optimal packaging processes

Temperature control

The set temperature is consistently maintained throughout the entire processing cycle.

To make it easier to open the package (e.g. a yogurt cup), a lower temperature can be set in the area of the opening tab.

Temperature profiling

Adjustable temperature zones

Improved seal quality at critical points such as triple layers and layer transitions

Targeted heat application between 2-layer and 4-layer areas