Digital Heating

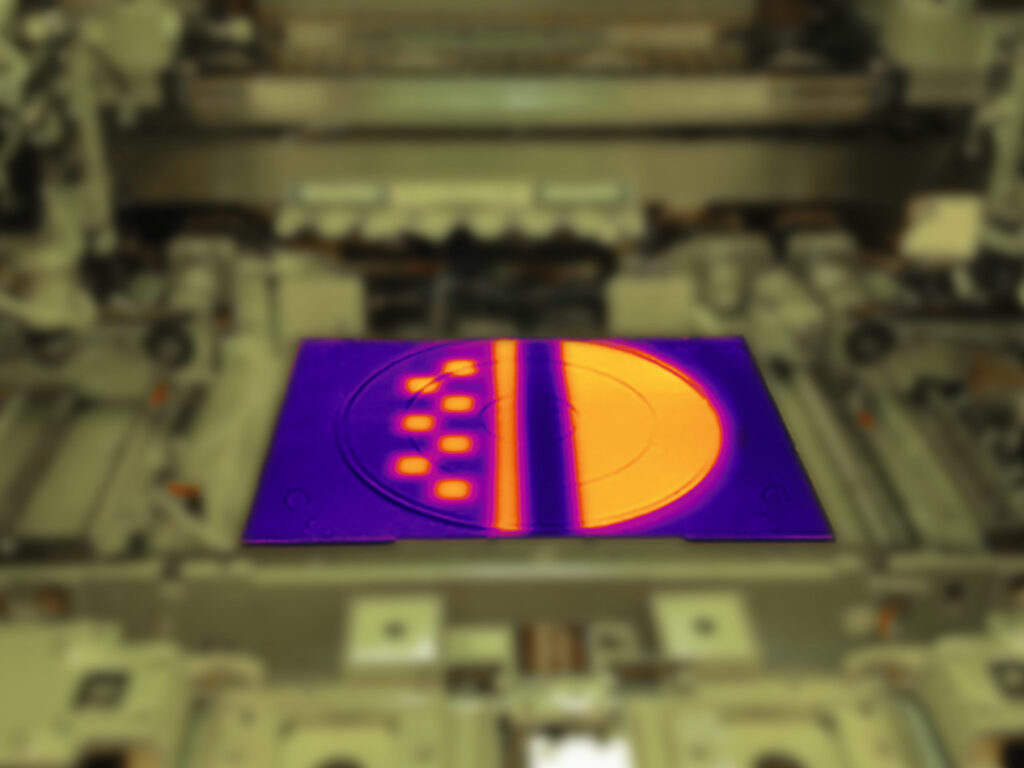

watttron's digital heating technology for the semiconductor industry

watttron's digital heating technology is an innovative heating system that enables precise, localized temperature control through a matrix of individually controllable heating pixels. The heating pixels are simultaneously temperature sensors, allowing real-time close-loop control of the temperature distribution.

Originally designed for the plastic processing in the consumer packaging field, this innovative technology is ideal for semiconductor applications requiring high-precision thermal management. For instance, during wafer processing or the fabrication of microelectronic components, maintaining exact temperature control is crucial to ensure product quality and yield.

Key Features of watttron digital heating technology

Fast cooling rates: when combined with cooling elements (currently mainly water cooling) up to 100 K/s

Extremely high heating rates: due to the low thermal mass of the heating pixel up to 450 K/s

Precise heating: maintaining 1 K temperature precision for every pixel also during the heat-up phase

Wide temperature range: from 35 °C (or colder, when combined with cooling system) up to 600 °C

Extremely high temperature gradients: when combined with cooling it is possible to reach and maintain a permanent temperature difference of 100 K over a distance of 5 mm

High heating power density: up to 180 W/cm2

Inert materials: the core material system was designed to have low outgasing characteristics, that makes them suitable for clean room, UHV and sensible applications

In-line process monitoring: the continuous monitoring of the electrical power needed to maintain the given temperature of every heating pixel, makes it possible to detect process deviations

Possibility to add auxiliary functionalities: since the heating elements are designed in-house, it is possible to print additional functionalities like microactuators or e.g. VIAs

Scalability: due to modular concept the heaters are adaptable to different tools and equipment sizes. Typical size of a heating pixel: square 5 mm × 5 mm but other shapes and sizes are possible

Real-time control: integrated process-near sensors ensure consistent process conditions

Control hardware integrated: operation via user interface (GUI) or protocols like: EtherNet/IP, ModbusTCP, MQTT, ProfiNet

Complete system: including the heater, control unit and user interface for seamless operation

Worldwide support: reliable service wherever you are

Contact Us

Do you have further questions?

You are welcome to

contact Klaudiusz Holeczek at any time.

Follow us at: