Monitoring

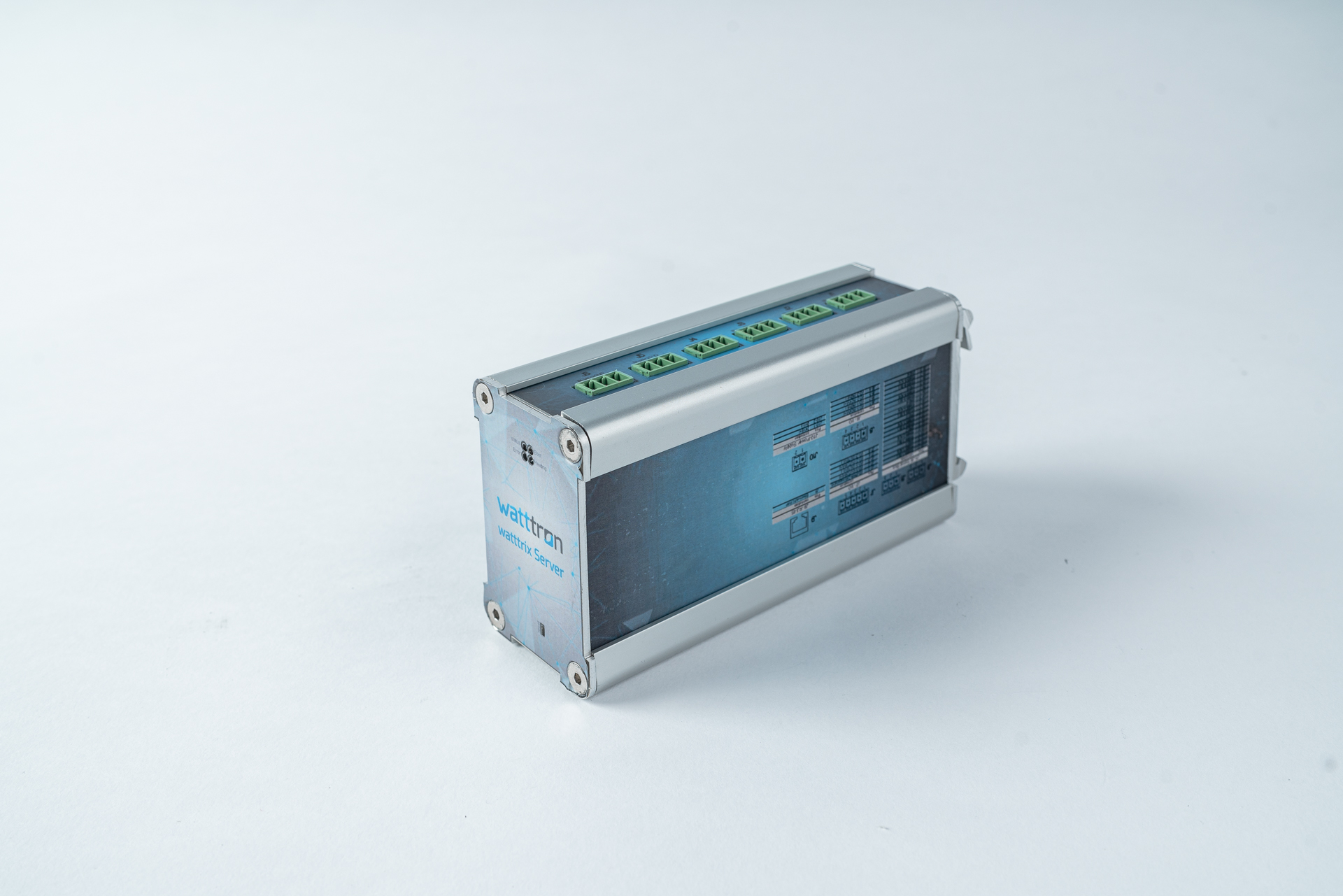

Visually supported control and monitoring.

Our technology is linked to a programmed image interface that essentially supports three functions:

- control: Supports visuall programming of the heaters.

- functional monitoring: mapping of the current production process and monitoring of errors. Thus reducing the effort in the installation of the machine itself.

- power monitoring: measures the current energy consumption of the system and detects anomalies in the production process. Thus taking over the quality monitoring and replacing expensive camera monitoring technology.

Contact us for more information!