Thermoform Technology

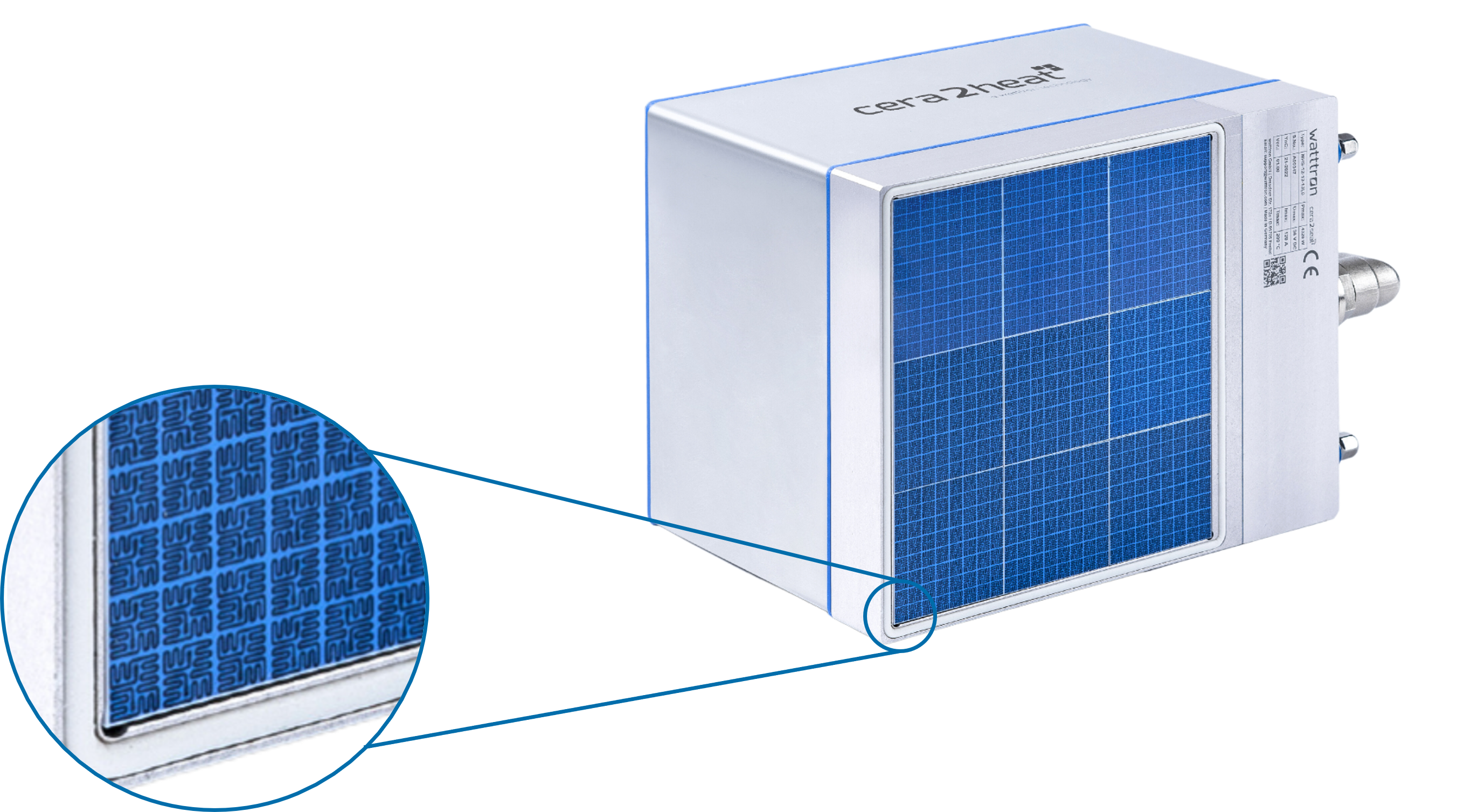

Watttron’s heating pixels are resistive heating circuits – typically 5 × 5 mm in size – applied to thin, electrically insulated ceramic substrates using a screen-printing process. Each pixel simultaneously functions as a temperature sensor.

The pixels are arranged in modular matrices and controlled via integrated electronics and a graphical user interface. A closed-loop feedback control system enables each pixel to maintain a precision of ±1 K and achieve heating rates of up to 10 K/s with power densities of up to 22 W/cm².

Greater efficiency through integrated heating and sensing technology

Heating

Each pixel functions as a Joule heater when current flows through its resistive path.

Sensing

The change in the pixel’s resistance with temperature provides real-time feedback and enables closed-loop control.

Intelligent heating surfaces for maximum process reliability

Rapid heating and cooling due to low thermal mass

Pixel-level control with full temperature monitoring ensures precise heating of the plastic web.

Minimization of material thickness through an optimized temperature profile

Completely reproducible thermoforming results without temperature deviation

Options for system integration