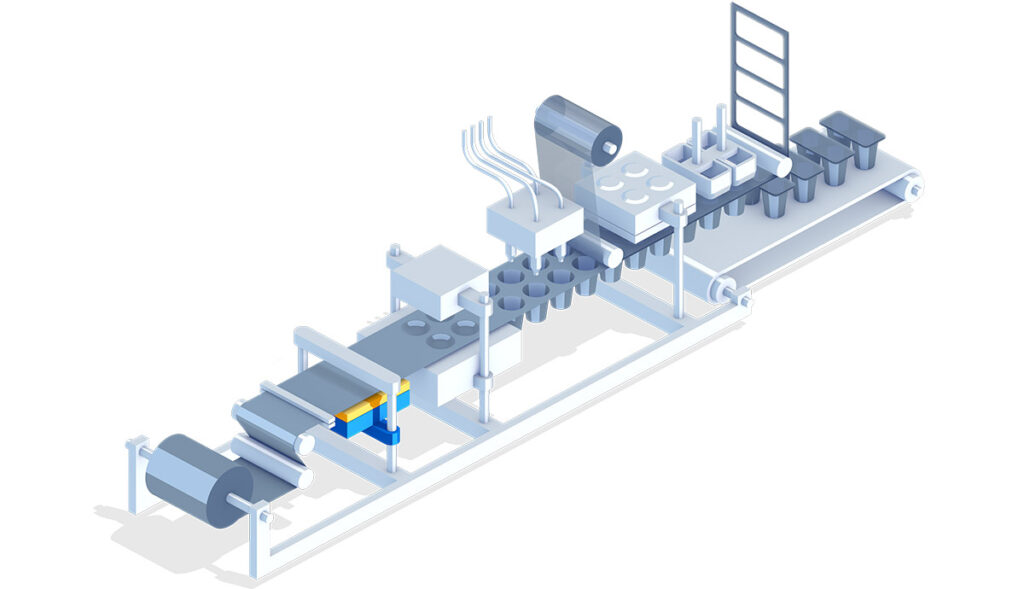

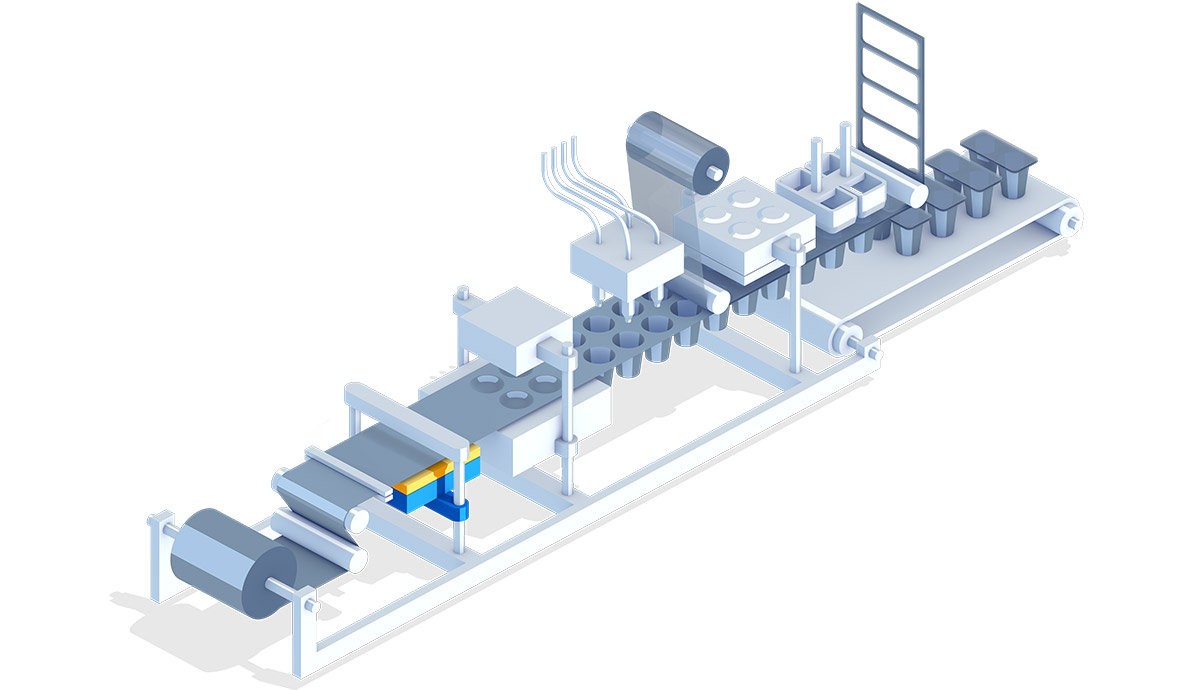

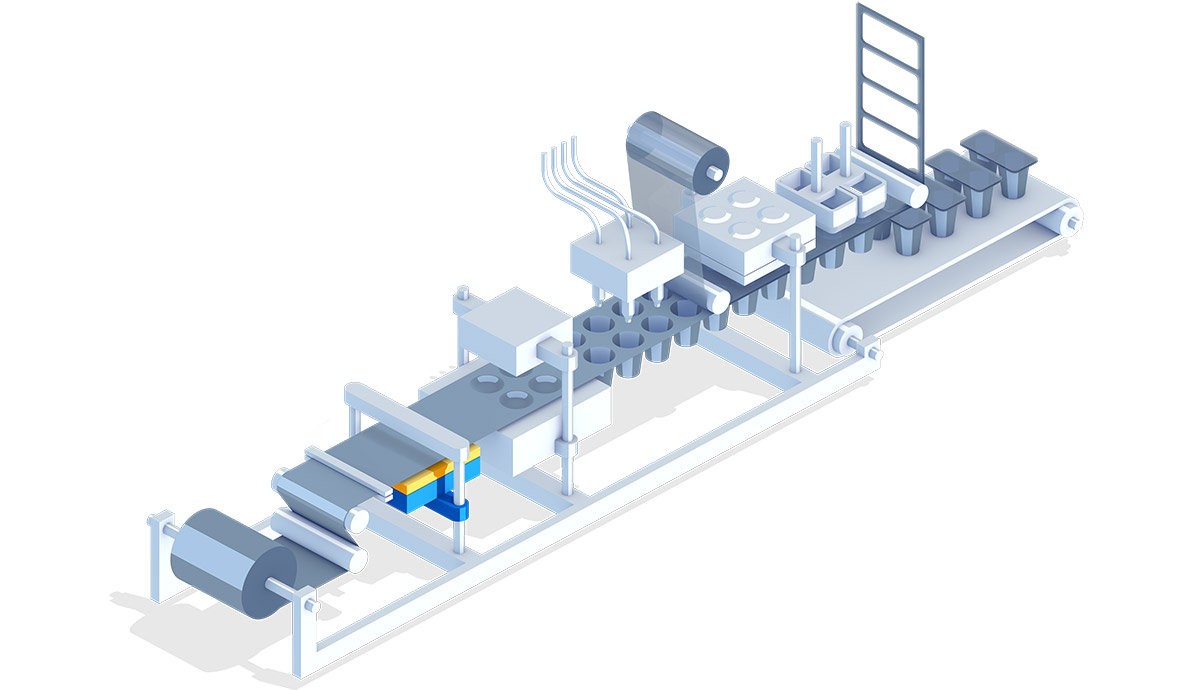

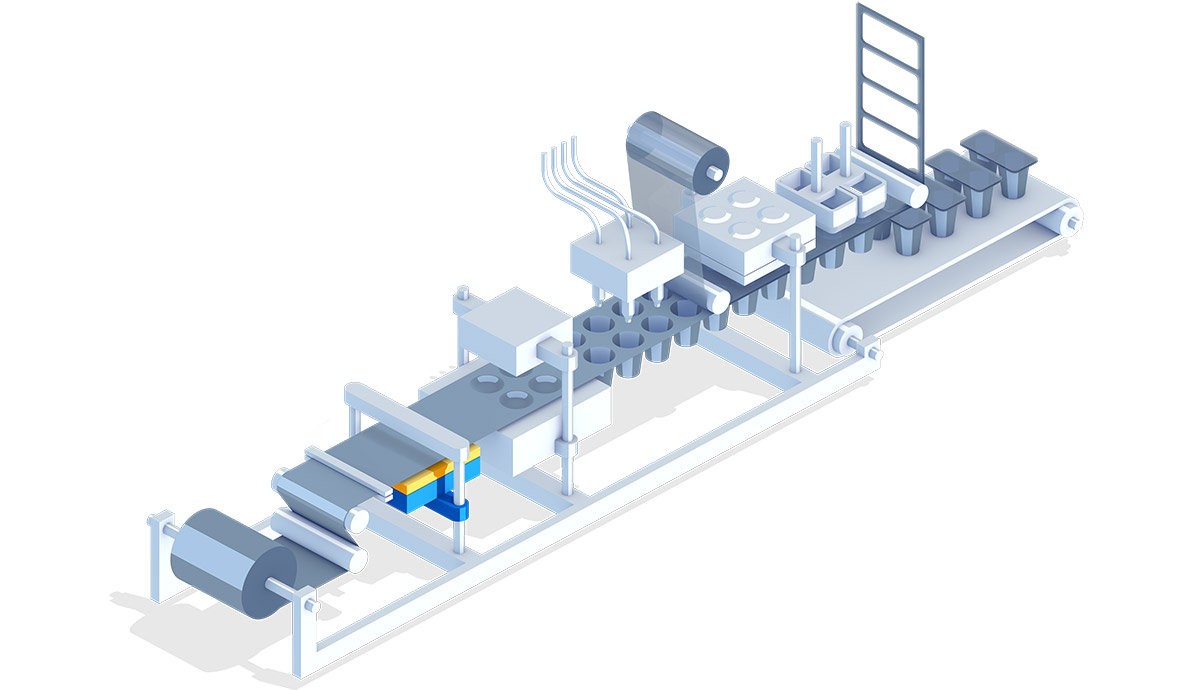

Thermoforming of rigid shells

One-sided preheating from below to form recyclable trays with optimal wall thickness distribution using a high-speed thermoformer.

The following challenges are addressed by watttron products:

-

Material savings of up to 50% in the bottom film

-

Reliable processing of recyclable mono-materials

-

Improved barrier properties and packaging stability

-

Forming high draw depths without using a plug assist

At Bayer, targeted heating of the PP film in a tablet blister using the Matrix heater reduced the packaging’s warpage by 16%, significantly minimizing a source of errors in subsequent processes.

In a packaging study for a 1-kg meat tray, the use of the Matrix heater achieved a uniform material distribution. The result: With mono-PP/EVOH, despite halving the original film thickness, the minimum residual wall thickness increased by an impressive 59% — the ideal condition for excellent barrier properties combined with reduced film usage.

For a customer in the sliced cheese sector, the use of the Matrix heater demonstrated an annual savings potential of €300,000. The original film thickness of the mono-APET packaging was reduced by 25% while maintaining the same level of stability.

Success Story

Bedford Increases Product Safety While Reducing Material Usage

Maximum product safety with minimal food waste and packaging material usage—that was the clear objective of this project. At a time when companies need to reduce their costs and environmental impact while guaranteeing the highest standards of hygiene and product safety, the focus was on two major challenges: using thinner packaging films to reduce plastic and costs and ensuring that the film is not damaged even under extreme production conditions.

Bedford, a premium meat and delicacies company based in Germany with a focus on traditional craftsmanship and high product quality, has been marketing sausage, ham, and convenience products for over a century. As an owner-managed family business based in Osnabrück, Bedford attaches great importance to product quality, sustainable thinking, and responsible production processes. “There is no substitute for quality” is a guiding principle that runs through all areas of the company.

In food production, Bedford uses a WEBOMATIC thermoforming machine as a central element at the end of the process chain: starting with meat processing, through breading, frying and deep-freezing, to final packaging. With a typical 3.1 format, in which, for example, 10 cutlets or several chicken nuggets are packaged, uneven material distribution during thermoforming, despite the pre-stretch stamp, previously led to local thin spots in the APET bottom film. These thin areas – some less than 70 µm – posed a risk during loading and transport. As experience has shown that a minimum of 70–90 µm of residual film thickness is required in the bottom film to reliably prevent punctures, e.g., from frozen breading.

Until now, this risk has been offset by 100% manual inspection by staff – a time-consuming and cost-intensive process, especially considering the shortage of skilled workers that is particularly noticeable in this industry.

Together with the machine manufacturer WEBOMATIC and the component manufacturer watttron, an innovative solution was implemented: the integration of watttron’s pixelwised heating technology (“matrix heater”) into the preheating system of the thermoforming machine. This technology enables precise temperature control, allowing the film to be shaped specifically during the thermoforming process and optimizing material distribution.

The cera2heat matrix heater consists of a field of 5 × 5 mm small heating pixels with integrated control electronics. This allows the temperature of each individual pixel to be controlled separately, enabling finely controlled temperature profiling in the forming area – far beyond the capabilities of conventional heating systems.

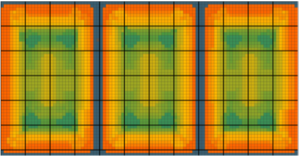

Figure 1: Temperature profile of 450µm APET film, 100mm draw depth

In practice, this means:

- The film is heated and stretched less where more material is needed

- Areas with high material thickness are heated to a higher temperature

- Overall, this results in a more even distribution of material, even in deep 100 mm packs, without local thin spots and without the use of pre-stretch punches

The conversion to digital heating meant that, even with a reduced film thickness of 450 µm (compared to the previous 550 µm), a minimum thickness of 100 µm was still achieved everywhere – well above the critical range of 70–90 µm. This not only improved product safety, but also significantly reduced plastic use, costs, and environmental impact.

Figure 2: Molded bottom film of the optimized packaging with a film thickness of 450 µm

The project has shown that intelligent thermal control is not only technically convincing, but also economically viable:

Reduction in film thickness

From 550 µm to 450 µm – this corresponds to a reduction of around 20% in material usage and leads to clearly measurable savings in costs and environmental impact.

Increased product safety

Even the previously thinnest areas, which could potentially be critical for punctures, were increased to a minimum residual wall thickness of 100 µm – well above the minimum required for safe packaging.

The watttron matrix heater has proven to operate stably and deliver reproducible results in typical food environments with daily wet cleaning, continuous loads and cool, humid conditions.

Figure 3: Matrix preheating integrated into WEBOMATIC thermoforming machine at Bedford

By integrating pixelwise heating technology, Bedford, WEBOMATIC and watttron have jointly demonstrated how modern digitalization in the packaging process enables sustainable film reduction while raising product safety and packaging quality to a new level.

This project is an example of how collaborative innovation between machine manufacturers and component suppliers can help transform traditional production processes, use resources more efficiently, and meet the highest standards of quality and safety—in line with the values that Bedford has stood for generations.

Applications

Food industry

Pharmaceuticals

Medical technology

Industrial goods

Packaging Types

Wiener Duo Pack

1 kg tray

10 Schnitzel Pack

Products

Matrix heating module

- Main component of a matrix heater

- Heated area size: 40 mm × 40 mm or 40 mm × 50 mm

- Each with 64 or 80 individually controlled heating pixels measuring 5 mm × 5 mm

- Temperature range: up to 200 °C

- Heating power: 22 W/cm²

- Non-stick coating or non-stick foil on the heating surface available

- Easy to replace

- Heating rate: 10 K/s

- By combining matrix heating modules, heating areas up to 800 mm × 800 mm can be realized

Complete price for matrix heater:

€64 per cm² of heating surface*

*Price for machine operators. Reduced pricing applies for machine builders.

Matrix heater standard (bottom or top heating)

- Compatible with all thermoformers for installation or retrofit

- IP65 rated

- Media supply via separate plug connectors

- Fixed position of the heating surface

Matrix top heater

- Optimized for the installation and retrofit of Multivac machines

- IP67 rated

- Fully integrated into thermoforming lids

- Adaptable to different film thicknesses with an adjustable heating surface position ranging from 0.2 to 1.7 mm behind the frame

- Media supply via connection block

Matrix preheater

- Optimized for the installation and retrofit of Multivac machines

- Compatible with drawer function

- Adaptable to various film thicknesses through adjustable heating surface position ranging from 0.2 to 1.7 mm behind the frame

- Frameless connection to the forming station for optimal use of film feed