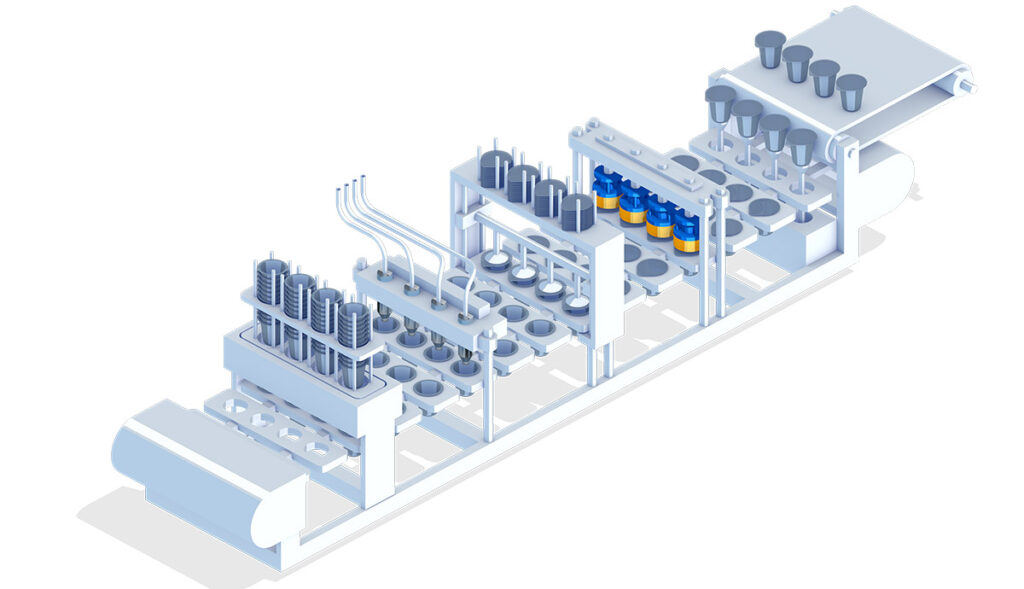

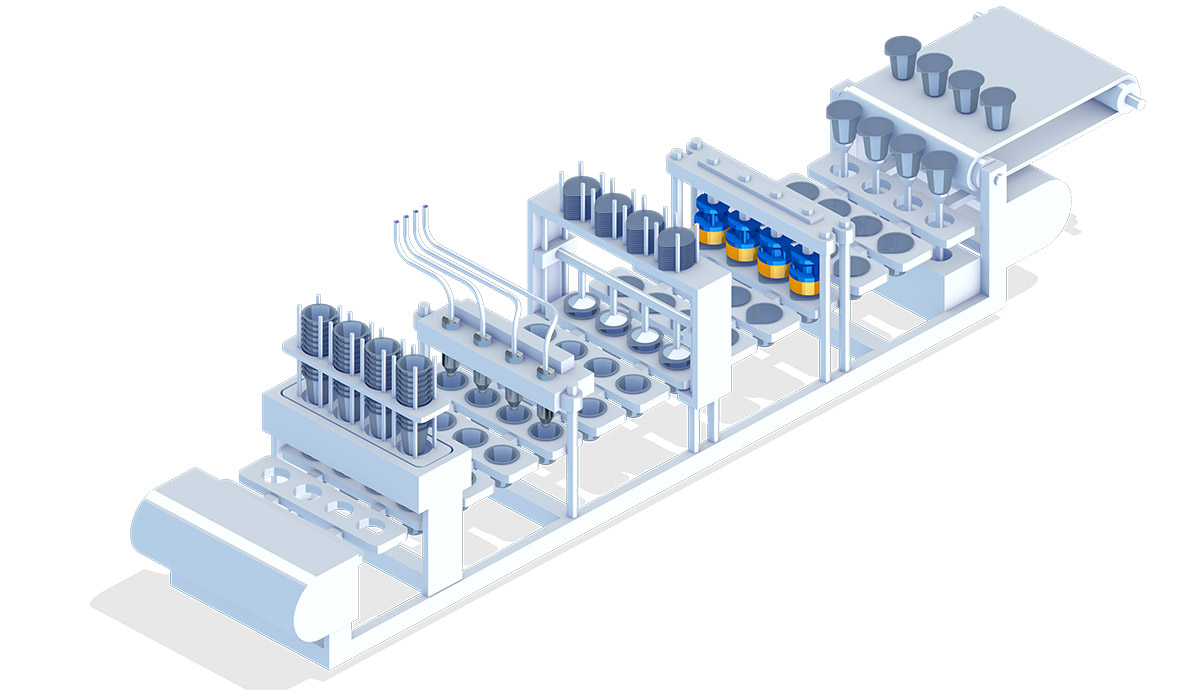

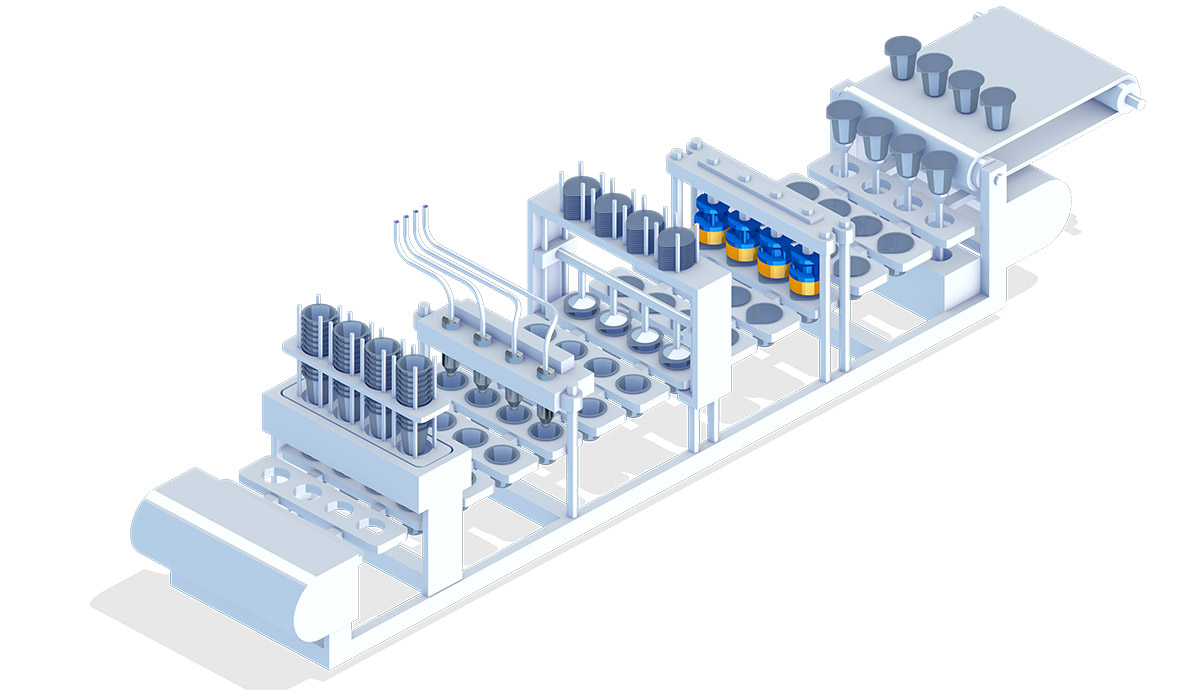

Cup FS (linear and rotary)

Our cera2seal sealing heads are designed for use in common FS cup filling and sealing machines for filling food, dairy products, or pet food. Integration into both existing* and new machines is straightforward and only requires appropriate adaptation of the machine mounting. Take advantage of the benefits offered by the cera2seal round and contour sealing heads:

- Processing of recyclable mono-materials at consistent machine output and constant high sealing quality

- No startup losses

- Up to 50% energy savings potential

- Use of a single sealing head for various lid materials—no material-specific sealing head changes required

- Integrated in-line quality control function

- Temperature profiling to reduce peel forces by locally adjusting sealing temperature in the tear tab area

In the case of retrofitting or upgrading existing systems, watttron offers a complete retrofit package. This includes not only the sealing heads and the necessary machine-specific connectors, but also a customized electrical installation, and, if required, stand-alone HMI control units as well as support during conversion and commissioning.

VDM anonym (PP + IQC)

Zott

Börlind

Ballerstaedft

Applications

Dairy industry

Delicatessen

Cosmetics

Pet-Food

Packaging Types

Made of plastic, glass, aluminum, metal, or fiber material

Round cup

Oval-shaped cup

Rectangular cup

Rectangular tray

Products

Round sealing heater SRHS

Our standard sealing head for the most common round formats combines the precise temperature control of the cera2seal product family with the requirements of the food and dairy industry — all at an attractive price point.

- Available format ranges / sealing diameters:

-

SRHS-0075: Outer sealing diameter: 74.5 mm (for D75 mm cups)

-

SRHS-0095: Outer sealing diameter: 94.5 mm (for D95 mm cups)

-

- Width and profiling of the sealing surface (e.g. groove): according to customer specification (max. width 5 mm)

-

Temperature range: up to 250 °C

-

16 individually temperature-controlled heating zones (pixels)

-

Typical heat-up rate: approx. 5 K/s

-

Machine-specific connection adapters

-

Optional: lid doming / bombage

-

Splash-proof design based on IP67

-

Housing made of food-safe materials (stainless steel and PEEK)

-

Design adaptation to existing machines upon request

Price: from €4,000*

* Standard formats with diameters of 75 mm and 95 mm. Price applies for a quantity of 1 unit.

The listed price is intended for machine operators/end customers. More favorable conditions for machine manufacturers (OEMs) available upon request.

Flexible round sealing heater SRHF

Our solution, especially for glass jar sealing applications where maximum sealing quality and defined opening behavior (peelability) are required — even with partially uneven sealing surfaces. The elastically mounted sealing segments ensure perfect sealing results, even on irregular surfaces.

- Available format ranges / sealing diameters:

-

SRHF-0062: Outer sealing surface diameter: 62 mm; inner sealing surface diameter: 29 mm

-

SRHF-0095: Outer sealing surface diameter: 95 mm; inner sealing surface diameter: 58 mm

-

- 16 individually temperature-controlled sealing elements, flexibly mounted (compensates for unevenness of up to 0.2 mm)

- Temperature range: up to 250 °C

- Typical heat-up rate: approx. 5 K/s

- Sealing profile shape: flat

- Ideal for sealing aluminum lids onto glass containers/jars

- Optional: vacuum suction of the lid at the sealing head

Price: from 6.000 €

** Depending on order quantity. The listed price refers to a quantity of 20 units.

The price applies to machine operators/end customers. More favorable conditions for machine manufacturers (OEMs) available upon request.

Contour sealing heater CSHC

Our contour sealing heaters feature a modular design that allows for flexible adaptation to a wide range of common cup and tray formats. The sealing heads and sealing geometries are customized according to customer specifications and format requirements.

-

Sealing geometry: according to customer specification

-

Various sealing shapes possible, e.g., oval, rectangular, or multi-cavity/chamber sealing

-

Depending on format and size: 8 to 40 individually temperature-controlled heating zones (pixels) per sealing head

-

Width and profiling of the sealing surface: according to customer specification (max. 5 mm)

-

Temperature range: up to 250 °C

-

Typical heat-up rate: approx. 5 K/s

-

Splash-proof design based on IP67

-

Use of food-grade materials for housing components (stainless steel and PEEK)

Price: upon request