With its new cera2heat thermoforming process, watttron promises packaging material savings of up to 50 percent, saving resources and costs. Packaging manufacturer GEA presented the system in operation at watttron‘s plant in Freital, Germany, to media, customers and investors

Freital, Germany, 9 December, 2024 – A new thermoforming process “cera2heat”, developed by German startup watttron, is capable of consistently producing uniform, thin-walled packaging shapes like yoghurt pots thereby reducing material use by up to 50 percent. With precise temperature control of individual “heat pixels”, the process can reliably handle mono-materials and also eliminate common packaging defects, including faulty shapes.

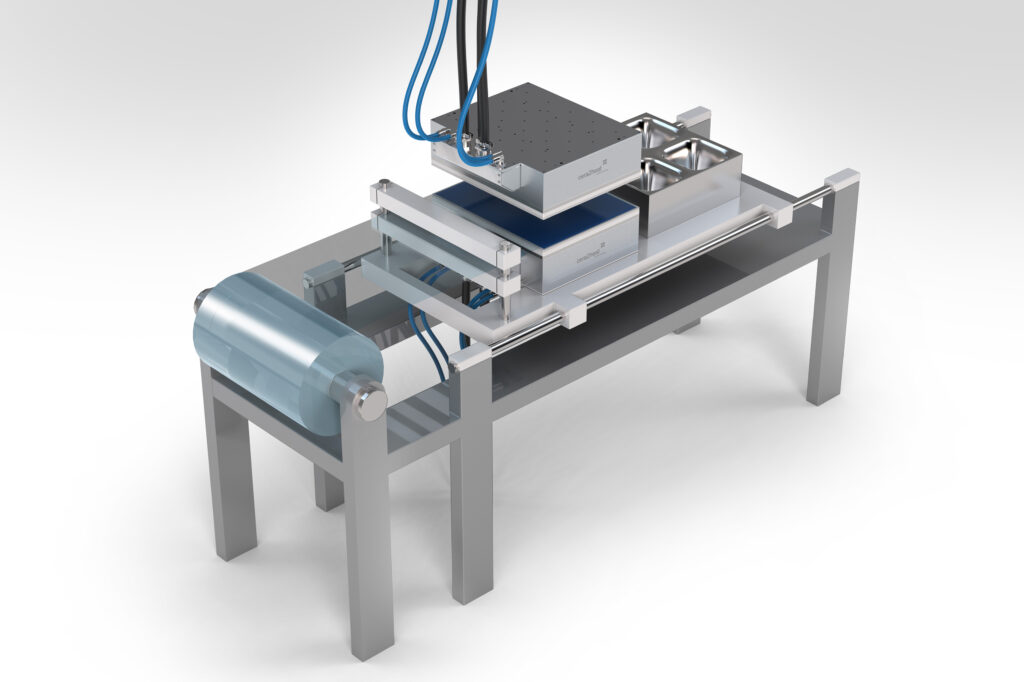

The patented cera2heat technology was presented to media, customers and investors at the watttron plant in Freital last week. Watttron cooperated with GEA who had integrated cera2heat into their machines for the live demonstrations on December 4. Cera2heat enables the optimization of packaging for food and beverages such as yoghurt and coffee capsules as well as meat and sausages. The process reduces material use by up to 50 percent compared with conventional thermoforming.

“The reduction in material leads to cost savings. While this depends on each individual case, we can say that on average it’s in the region of five to six figure Euros annually,” says Dr. Sascha Bach, Chief Technology Officer at Watttron.

More consistent packaging despite thinner base material

A cost-effective packaging choice for perishable and durable products alike, thermoforming applies heat to a polymer film to create a desired shape. Traditional thermoforming has a

single temperature setting and therefore heats the material uniformly, rather than targeting known problem zones: The bottom corners of the cavity are often affected by

thinning, an issue for overall packaging strength. To give the container the necessary stability, manufacturers may use thicker base material.

Watttron’s cera2heat system can generate defined heterogeneous heating fields for problem areas using a large number of individually controllable small heating pixels. This allows the polymer film to be heated in a targeted manner and the flow behavior of the material to be optimally adapted to the desired packaging shape. This ensures a uniform wall thickness and therefore stable packaging but with a much thinner plastic film, significantly reducing the amount of material used.

Watttron’s heating system consists of multiple square 5-millimeter heat pixels, around the same size as a pencil eraser. The temperature of each pixel can be individually programmed and controlled to cope with varying heat requirements – up to 200 degrees Celsius – across the entire packaging shape. The pixels are arranged in 40 x 40 millimeter modules in any order and combination, which allows for an unlimited heating area, an advantage for thermoformed packaging with different geometries. With cera2heat thermoformed packaging can be produced optimally, saving resources and costs at the same time. Because the wall thickness of the molded part is more homogeneous, a thinner plastic film can be used for the same product. The packaging manufacturer saves material and costs.

Optimal shaping even for complex geometric shapes

“With our cera2heat, any plastic film can be heated to suit the desired thermoforming geometry. Surfaces that need to be formed more acutely can be heated more strongly than areas that are formed less or not at all. This system helps distributing the material as desired,” says Bach.

A positive effect of the increased functionality is the system’s low energy costs compared to conventional thermoforming heating systems. The heater heats up efficiently and can remain switched off during cycle breaks. This means that up to 30 percent energy can be saved because the heterogeneous heating of the surface makes targeted use of the energy.

The exact temperature of the individual heating pixels is visualized on a screen during production. Individual pixels can be specifically controlled and heated differently if required. The cera2heat system can be retrofitted or integrated into production lines.

Advantages when processing mono-materials

“Cera2heat has already proven its value in terms of quality and material savings. Mono-materials will play a much greater role in all packaging in the coming years, and cera2heat will therefore be a reliable companion on packaging machines,” says Bach.

Mono-materials offer both cost-effective recycling and a viable alternative to mixed materials, which are notoriously difficult to separate. However, materials such as polypropylene still pose a challenge in thermoforming as they need to be processed within a narrow temperature range. This increases the challenges for the thermoformed packaging industry.

The packaging market is increasingly demanding in terms of product aesthetics, performance and cost – and the industry has responded with improvements in design and manufacturing technologies. This includes many advances, including this heating pixel-based technology, cera2heat.

Watttron customers currently using the cera2heat process include GEA and Multivac.

For the cera2heat matrix heating system, watttron was awarded the German innovation award for climate and environment (der deutsche Verpackungspreis für Klima und UmweIt – IKU) and the German Packaging Award.

At its lab at the watttron Freital Technology Center, a team is working on further areas of application. For example, watttron has developed cera2seal, a seal-heating system that reliably seals even complex geometric packaging.

About Watttron

A startup company established in 2016, watttron specializes in digital heating technologies that allow precise processing of mono-materials, a preferred choice for recyclable packaging. Through its patented engineering technologies, Watttron supports manufacturers by reducing the complexity in recycling, minimizing waste and complying with increasingly stringent sustainability regulations.

Developed at watttron’s Headquarters in Freital, Germany, the proprietary digital heating solutions, including the award-winning cera2heat and cera2seal systems, help ensure that packaging materials are processed efficiently, supporting the shift towards environmentally friendly practices in a range of industries.

Since its inception eight years ago, watttron has opened a subsidiary in the US and has won 14 engineering, innovation and business awards, including the prestigious Sustainability Awards, Deutscher Verpackungspreis Gold (German Packaging Award), World Star Award and the International FoodTec Award Gold.

In March 2024, the company secured €12 million from Circular Innovation Fund, as part of series B funding.

Media contacts:

For Watttron

Malene Conlong

Malene.conlong@presspro.eu

+491716992650

Sandra Weiner

Head of Marketing

Sandra.weiner@Watttron.com