Thermoforming

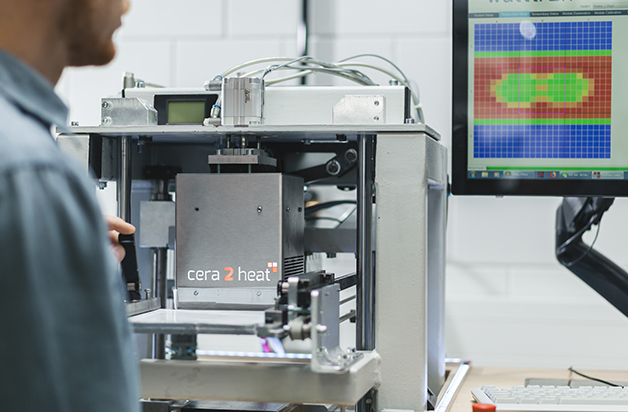

cera2heat: The most sustainable method of

thermoforming.

Sustainability and efficiency are not short-term trends – they are the future. And we offer the solutions for them. For all industrial sectors. For the most diverse applications. And as customized developments for customer-specific requirements.

Our patented cera2heat® matrix heating system enables heterogeneous, precisely defined contact heating of surfaces.

It is based on a large number of regularly arranged, small heating pixels. The temperature of each pixel can be individually programmed and controlled. Analogous to a TFT screen, the precise control of the heating pixels can be made visible as a thermal image.

The heating system consists of 40 x 40 mm modules. These can be arranged in any order and combined to form individual areas. Thanks to its modular design, cera2heat® can be installed or retrofitted in almost any machine.

Technical Data

Heating rates: up to 100 K/s

Temperature range: up to 200°C (higher temperatures on request)

Power range: up to 50 W/cm²

Production ready within a few seconds

Realizable heating area: practically unlimited due to modular concept

Size of a heating pixel: 5 mm × 5 mm

Size of one module: 40 mm × 40 mm (8×8 heating pixels)

Integrated temperature sensors on heating surface for optimal

process control and temperature control accuracy

Control hardware integrated, operation via user interface

(GUI)

or by integration into machine control system

Contact us for more information!